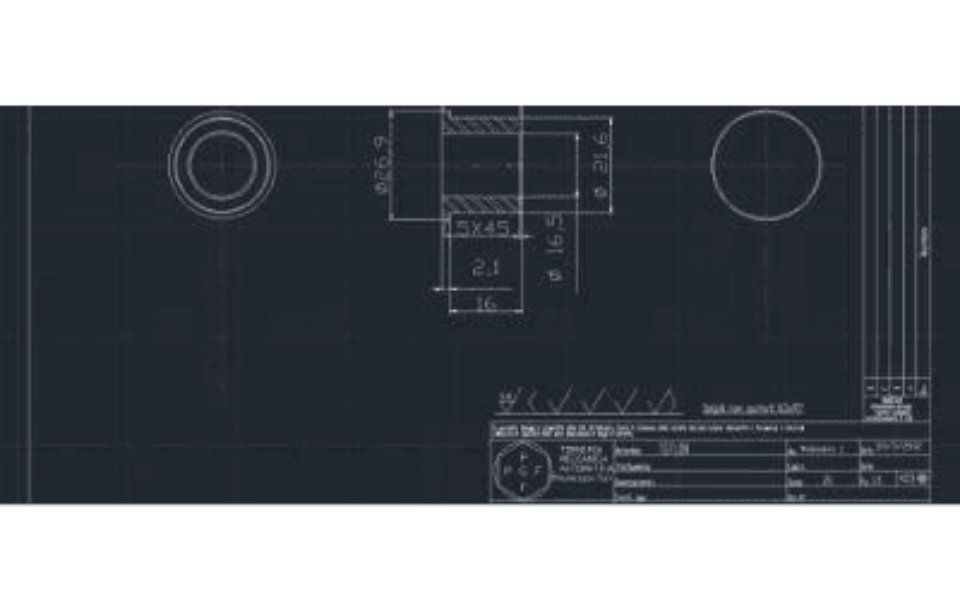

Turned prototypes to design

PGF manufactures turned prototypes to design or small production batches in quick turnaround times. We entrust the machining to experienced staff and technologically advanced CNC lathes to minimise machine setup times, ensuring an excellent quality/price ratio. Our prototypes are produced with great precision in aluminium, stainless steel, brass, and other materials suitable for chip removal.

Prototyping and product engineering

The prototyping and product engineering phase allows client companies to create a product while understanding in detail the strengths and weaknesses of the production process. It also helps determine whether the project can be realised or needs to be developed in another way. We conduct tests, modifications, and improvements on the prototypes to reach the final version.

In response to the needs of a market where cost reduction is crucial, PGF srl, thanks to the know-how developed over the years in turning and milling, is able to support its clients from the design phase, advising on the most cost-effective solutions during production. In this way, the client can benefit from the specific expertise acquired by PGF srl over the years and keep product costs as low as possible.

Contact us for more information about our products and services