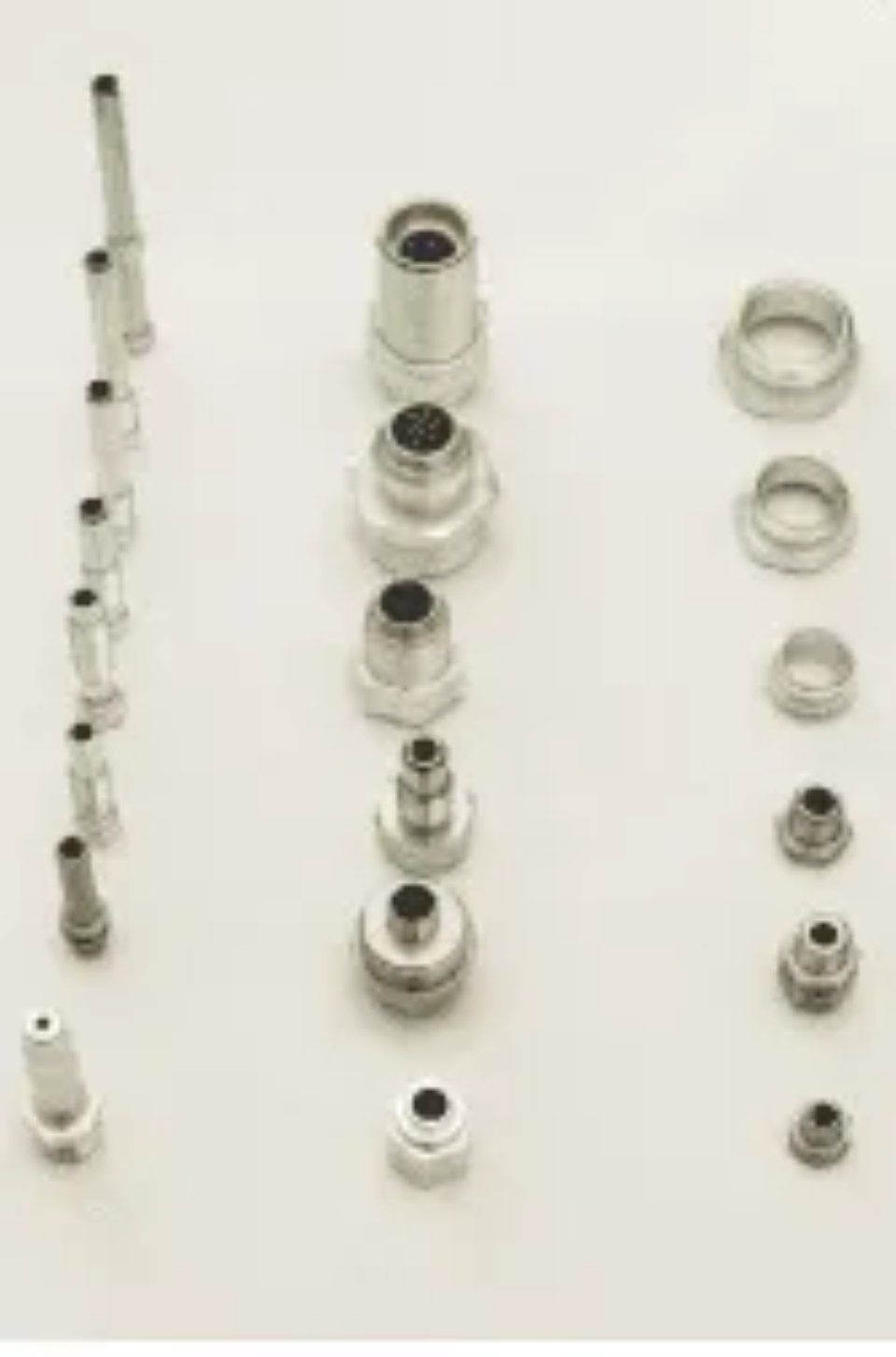

Turned and milled bar components

Specific treatments on metals

PGF srl is involved in the production of customer-specific turned and milled bar components, from a diameter of 2 mm to 65 mm, thanks to the use of technologically advanced machine tools. The materials used for the production of turned products can include automatic steels, high-strength steels, carburising steels, stainless steels, as well as aluminium and brass alloys.

The production batches of

milled and turned bar components range from a minimum of a few hundred pieces to a maximum of over 100,000 pieces. The company is also able to produce prototypes and samples quickly and presents itself to clients as a reliable partner for the development of new products. In addition to the production of turned and milled bar components, Tornerie P.G.F carries out treatments on metals of various types and metal alloys, including:

- internal and external grinding using traditional and latest-generation CNC grinding machines;

- industrial precision grinding;

- electroplating, to treat previously cleaned, degreased, and acid-treated metal surfaces, giving them specific aesthetic qualities, resistance to oxidation and corrosion, and increased hardness;

- bright chrome plating, which increases corrosion resistance while improving coating adhesion;

- matt chrome plating for components of machinery and equipment;

- heat treatments;

- polishing;

- surface finishes;

- anodising, with the aim of giving steel the crystalline structures that confer specific mechanical and/or technological properties to the turned and milled bar components.

Contact us for more information about our products and services