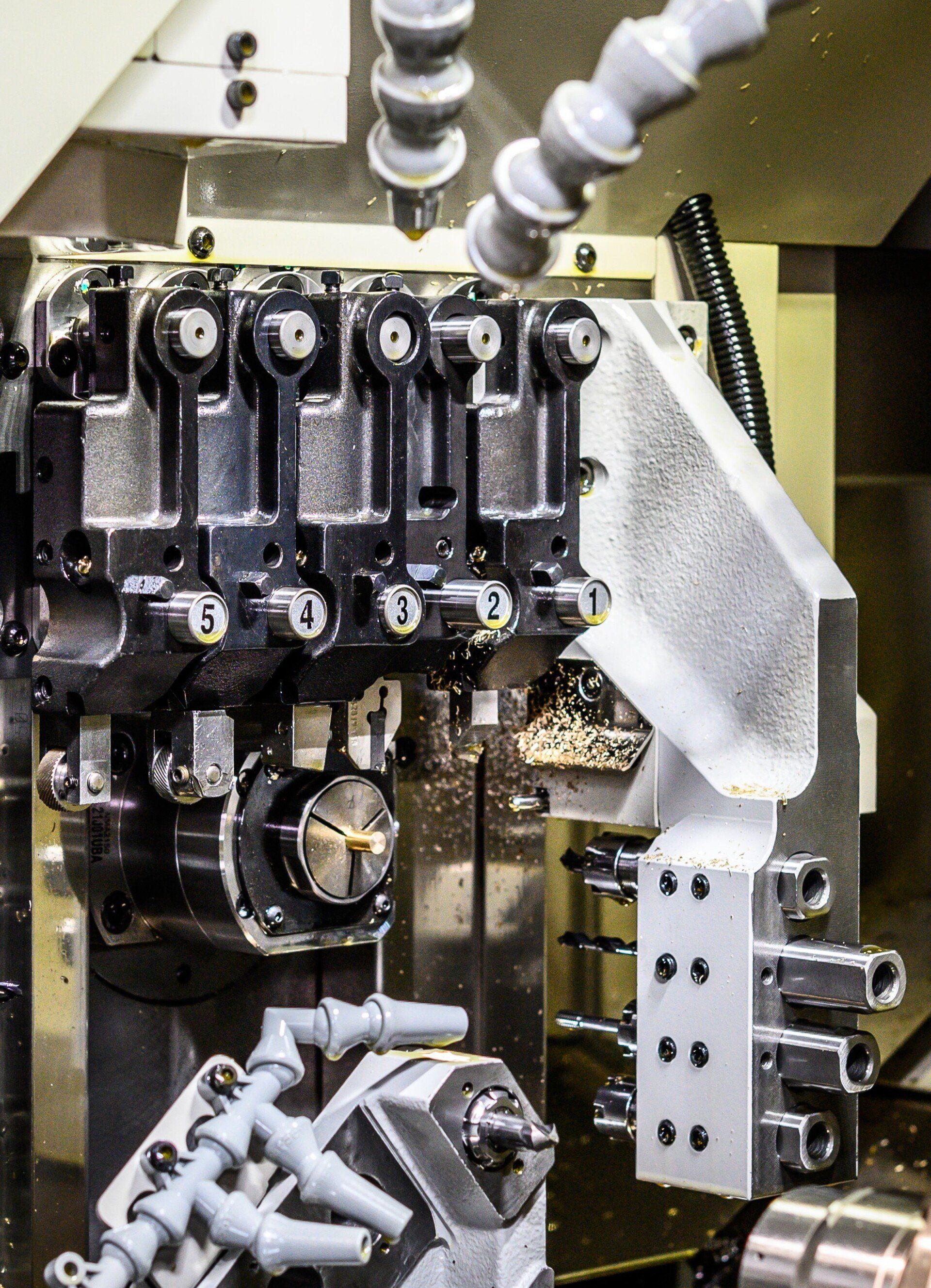

CNC turning of stainless steel

PGF is at the forefront of mechanical processing and CNC stainless steel turning. In particular, the company is a recognised entity not only in Turin but across Europe, known for the quality of its work and the production of custom-made parts in various types. Within the production department, there is an area dedicated to quality control, which monitors every phase of the machining process and the finished part once the process is completed. PGF operates under the ISO 9001:2015 certified quality management system to guarantee its customers excellent products at competitive prices.

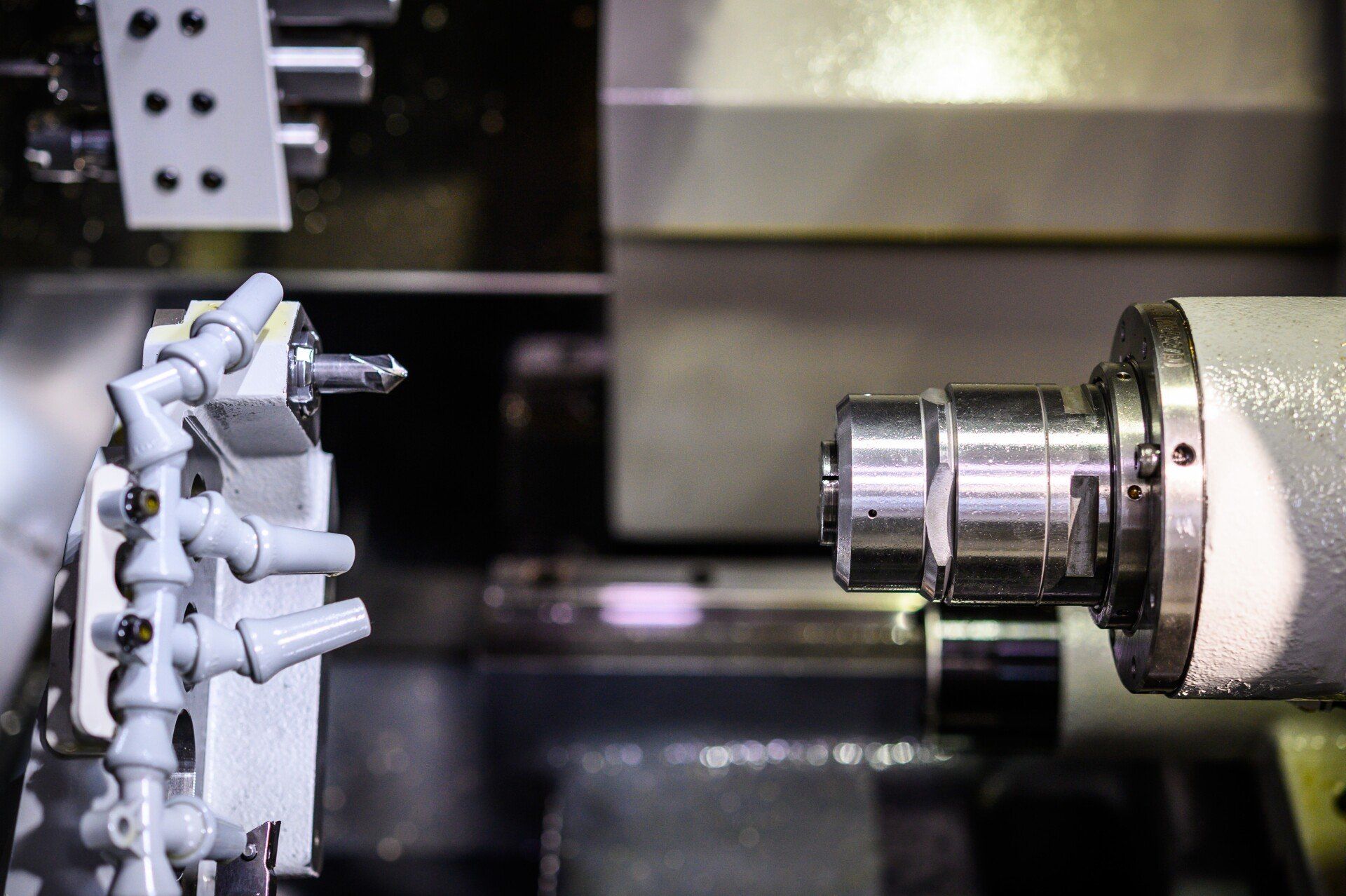

CNC lathes with fixed head

Mupem Win 6500, 8 controlled axes, max bar diameter 65mm Cami B 60, max bar diameter 60mm

Gildemeister Sprint 42, 8 controlled axes, max bar diameter 42mm

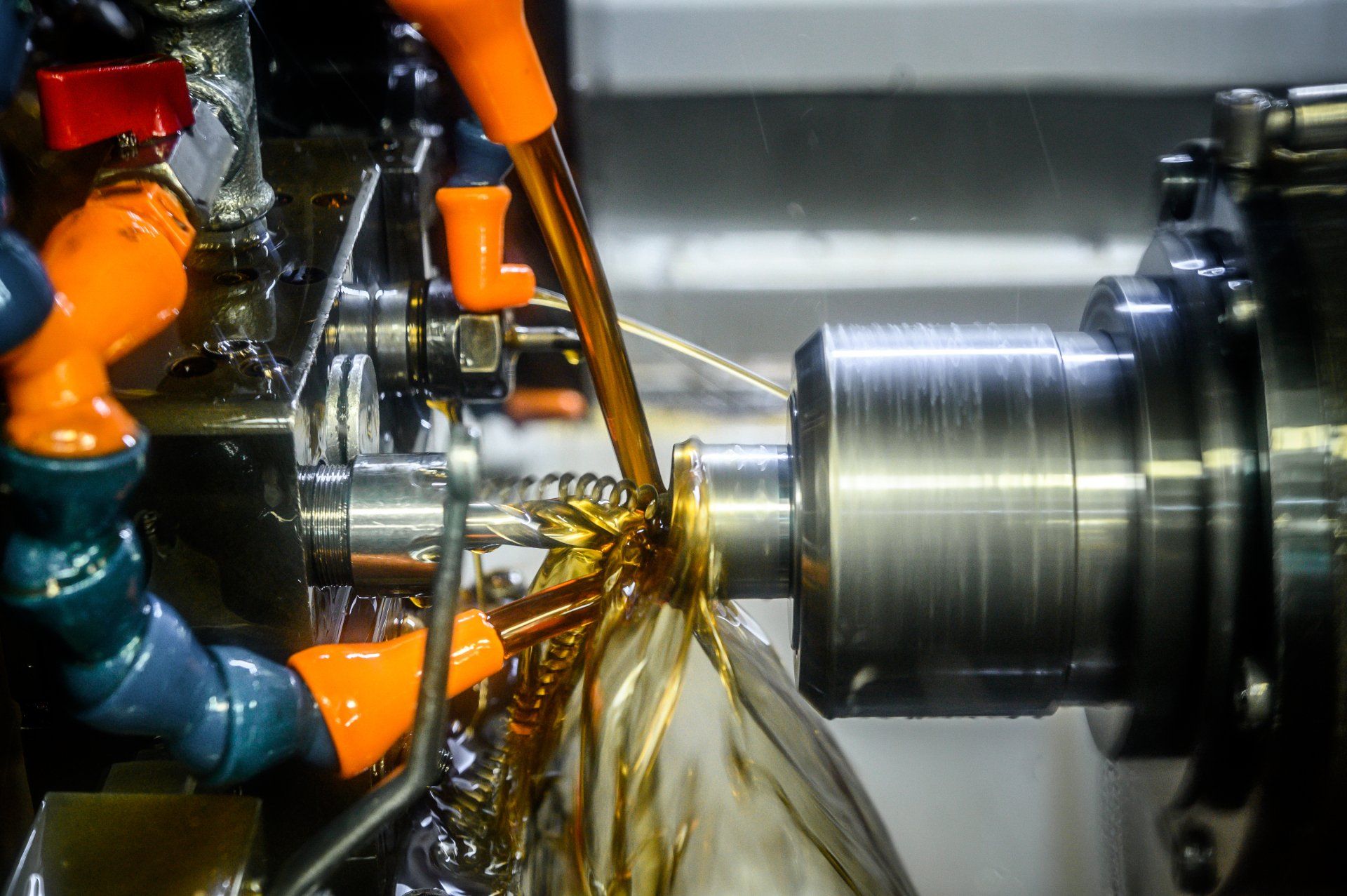

CNC lathes with mobile tailstock

Gildemeister SPEED 32-10, 10 controlled axes, max bar diameter 38mm (machine suitable for the production of long parts and deep drilling) Gildemeister SPEED 20-8, 8 controlled axes, max bar diameter 20 Gildemeister GLD 20, 5 controlled axes, max bar diameter 20mm Hanwha ML 26, 4 controlled axes, max bar diameter 26mm Nomura YB 32, 8 controlled axes, max bar diameter 32 (machine suitable for the production of milled parts) Nomura NN 20 J2, 8 controlled axes, max bar diameter 20mm.

Contact us for more information about our products and services